Straw Bale Code Supporting Documents and Testing Results

This page is a repository for supporting documents for Appendix S – Strawbale Construction, which is included in the 2015 International Residential Code (IRC).

A Code Change Proposal for this appendix was submitted to the International Code Council (ICC) on January 3, 2013, with final revisions made on Feb 27, 2013. The proposal was approved with a 9-1 vote by the IRC Building Committee at the ICC Committee Action Hearings in April 2013. On October 4, 2013 the proposal received final approval at ICC’s Public Comment Hearings. In May 2014 Appendix S was published in the 2015 IRC.

On this page you will find testing reports, research papers, professional and academic journal papers, support letters from licensed design professionals, and other references. This page was established on Dec 26, 2012. (Most recent update – June 4, 2014)

Please direct all inquiries to Martin Hammer: mfhammer@pacbell.net or 510-525-0525

Strawbale Construction Appendix for the 2015 IRC:

IRC 2015 Appendix S – Strawbale Construction

Text of the Strawbale Construction appendix as it appears in the 2015 International Residential Code (IRC). Commentary and illustrations for Appendix S will appear in the 2015 IRC and Commentary publication (expected availability July 1, 2015).

Support Letters from Licensed Design Professionals

**Support Letters for Proposed IRC Appendix R – Strawbale Construction**

Support letters from 2 Structural Engineers, 4 Civil Engineers, 1 Professor of Civil Engineering, 5 Architects

Recommended Provisions for Engineered Strawbale Construction

Recommended Building Code Provisions for Engineered Strawbale Construction (not codified)

Fire Test Video

Structural Use

Load-Bearing Straw Bale Construction

A summary of worldwide testing and experience (Bruce King, PE)

**Vertical Load Calculations**

Structural calculations for vertical loading (Kevin Donahue, SE)

Out-of-Plane Load Test

Test report of walls with different combinations of plaster and mesh to resist out-of-plane loads. (Kevin Donahue, SE)

**Out-of-Plane Load Calculations**

Structural calculations for out-of-plane loading (Kevin Donahue, SE)

Out-of-Plane Load Calculations – Supplemental

Supplemental structural calculations for out-of-plane loading (Kevin Donahue, SE)

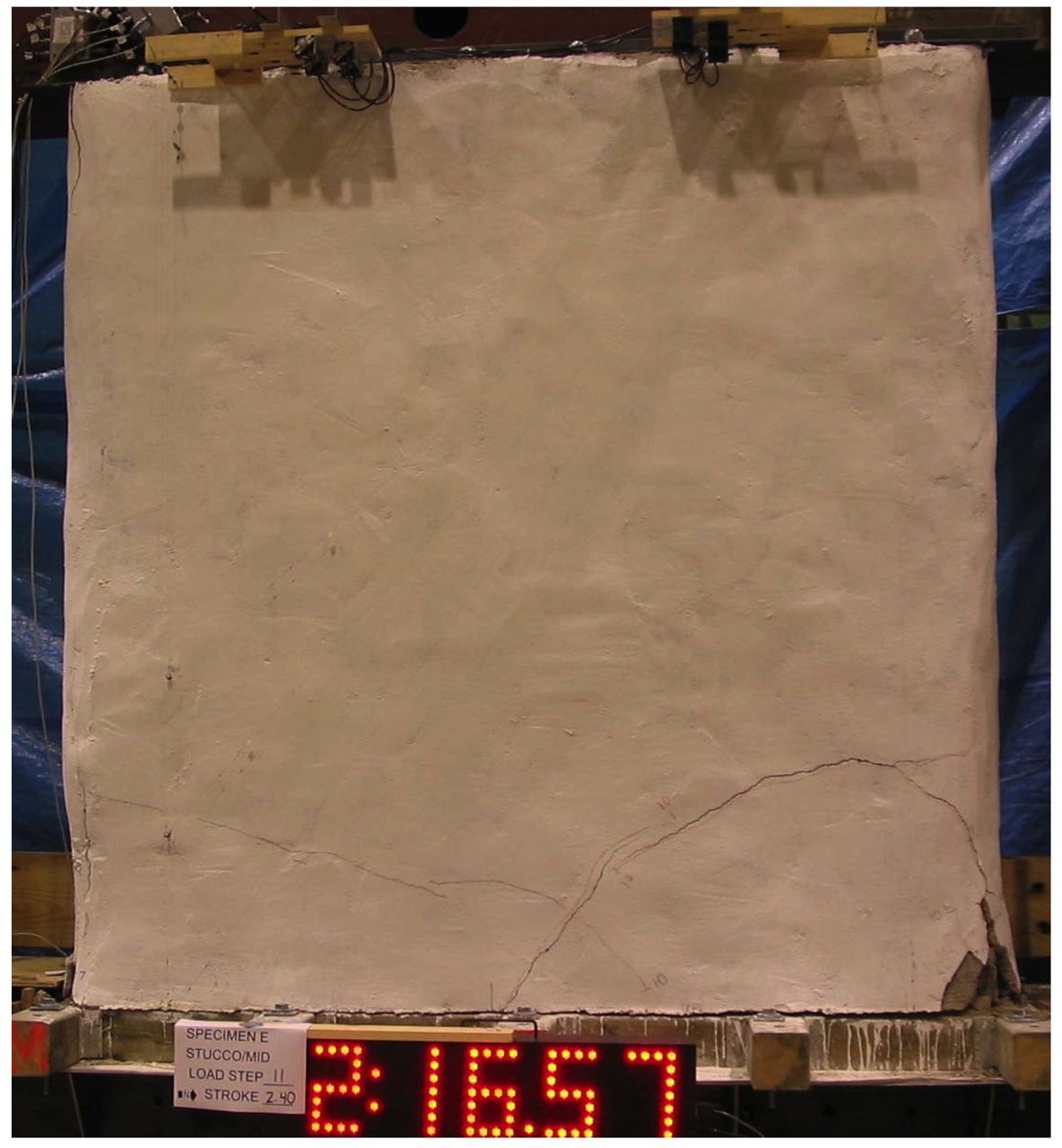

In-Plane Cyclic Tests of Plastered Straw Bale Walls – U. of Illinois

Testing report on 3 earth-plastered and 3 cement-plastered 8’x8′ straw bale wall specimens (Cole Ash; Mark Aschheim, PE; David Mar, SE)

In-Plane Cyclic Tests of Plastered Straw Bale Walls – U. of Washington

Thesis on testing of 2 cement-plastered 8’x8′ straw bale wall specimens (J.Ramirez)

In-Plane Cyclic Test of Plastered Straw Bale Wall – California Polytechnic University

Thesis on testing of 2 cement-plastered 4’x8′ straw bale wall specimen (S.Faurot; K.Kelly; H.Kim)

In-Plane Monotonic Test of Plastered Straw Bale Wall – California Polytechnic University

Thesis on testing of cement-plastered 8’x8′ straw bale wall specimen (J.Nichols; S.Rapp)

Shake Table Test Video of Full Scale Building Specimen – U. of Nevada, NEES Facility

Video of 14’x14’x10′ clay-plastered straw bale building specimen constructed with shaketablesbbldgtestunrphotosystem developed for earthquake affected Pakistan (Darcey Donovan, PE)

** Basis for Prescriptive Use of Plastered Strawbale Walls as Braced Wall Panels in the IRC**

(added 3.7.13)

Derivation of minimum total length for strawbale walls used as prescriptive braced wall panels in the IRC. (M.Aschheim, PE; M.Hammer, Architect )

** Seismic Design Factors and Allowable Shears for Strawbale Wall Assemblies**

Recommended seismic design factors and allowable shears, including P695 analysis and analysis of in-plane testing results. (Mark Aschheim, PE, et al.

Mesh Anchorage Details for Straw Bale Walls

Analysis of testing of mesh attachment to boundary members. (A.Parker, M.Aschheim, PE, et al)

Straw Bale Wall Stiffness

Analysis of stiffness compared with plywood shear walls and concrete shear walls. (K.Donahue, SE)

Moisture Conrol

Moisture Monitoring – Ridge Winery

The Ridge Winery near Healdsburg, California, is one of the largest straw bale buildings in the world. With straw bale walls up to 23 feet high, coatings of different types of earthen and lime plasters, and many different moisture loading conditions.

Straw Bale House Moisture Research Summary

Canadian Mortgage & Housing Corporation straw bale house moisture research summary

Moisture and Thermal Conditions for Degradation of Rice Straw UC Davis PhD thesis on straw degradation

Moisture Properties of Straw and Plaster/Straw Assemblies

Tests of straw bales and plastered straw, for capillary, permeability, and sorption isotherms (John Straube, PE)

Fire Reistance

1-Hour Fire Resistance of a Non-Loadbearing Wall w/ Earth Plaster

A 12 ft x 14 ft non-loadbearing wall constructed with 7.5 pcf rectangular wheat straw bales stacked in a running bond pattern, clad on each surface with 1″ of earthen-plaster, produced, assembled and tested herein, successfully met the conditions of acceptance as outlined in ASTM Method E119-05a Fire Tests of Building Construction and Materials for a fire-resistance rating of 1-hour.

2-Hour Fire Resistance of a Non-Loadbearing Wall w/ Cement-Stucco

A 10 ft x 10 ft non-loadbearing wall constructed with 7.5 pcf rectangular wheat straw bales stacked in a running bond pattern, clad on each surface with 17 GA stucco netting and 1″ of cement/stucco, produced, assembled and tested as described herein, successfully met the conditions of acceptance in ASTM Method E119-05a Fire Tests of Building Construction and Materials for a fire-resistance rating of 2-hours.

ASTM E84 Test Report: Surface Burning Characteristics ofStraw Bales

Test report indicating a flame spread index of 10 and smoke developed index of 350 for unplastered bales.

Thermal Insulation

Thermal Performance of Straw Bale Wall SystemsThermal Performance of Straw Bale Wall Systems

Results from thermal tests, particularly the Oak Ridge National Laboratory test, are reviewed, analyzed, and discussed in a summary report.

Thermal Performance of Straw Bale Wall Systems, by Nehemiah Stone, 2003

Finishes

Properties of Earth, Lime, and Lime-Cement PlastersProperties of Earth, Lime, and Lime-Cement Plasters

Compressive strength, modulus of rupture, shrinkage, erosion, and modulus of elasticity. (Kelly Lerner, Architect; Kevin Donahue, SE)

Design of Straw Bale Buildings; the State of the Art

Design of Straw Bale Buildings; the State of the Art